Adjustment of photoelectric switch of pallet wrapping machine

The pallet wrapping machine is a device that detects objects through photoelectric sensors and wraps objects. In this process, the role of photoelectricity should not be underestimated, especially in the first test machine, the adjustment of the photoelectric switch is particularly important, and it is important for the subsequent use of the equipment. It plays a vital role. The following article will share with you how to adjust the photoelectric switch of the pallet packer.

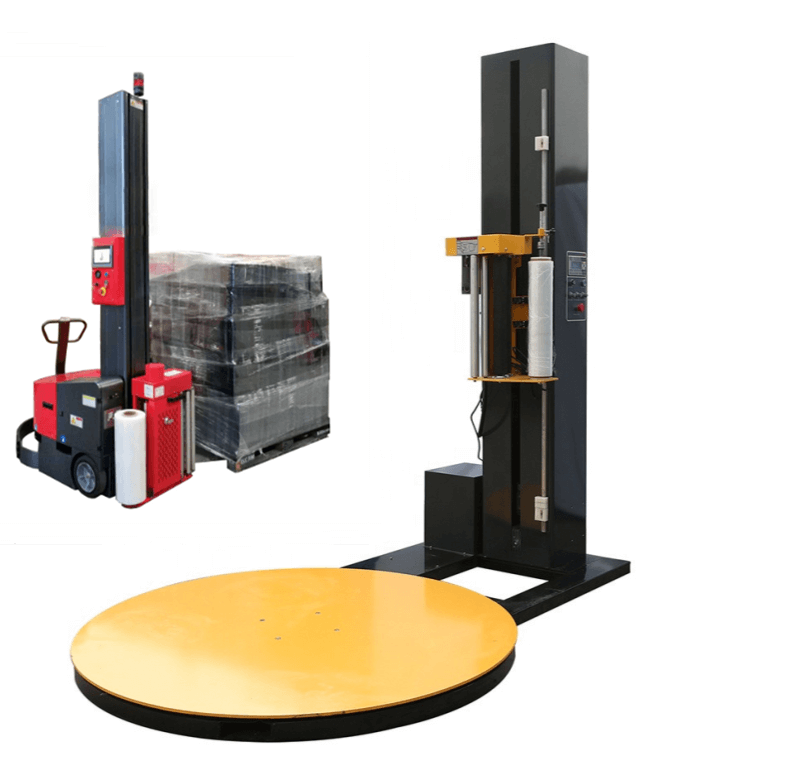

1. Adjust the normally open point of the photoelectric switch. As shown in the figure, let the photoelectric switch be in a normal working state and start other processes.

2. Test the photoelectric. The photoelectric test is divided into 3 steps:

1) When the equipment is powered on and there is no cargo. The green and red indicator lights are always on.

2) After sensing the goods, only the green light should be on.

3) During the operation of the equipment, the film frame exceeds the height of the cargo, and both the green and red lights are always on.

3. Confirm that the knob is adjusted to the “L” gear. When the status of the indicator light is not correct, adjust the photoelectric sensing distance. At this time, it should be divided into 2 steps:

1) If the distance of the photoelectric sensing goods is increased (far), the turntable knob is adjusted to the MAX direction.

2) If the distance of the photoelectric sensing cargo is reduced (near), the turntable knob is adjusted to the MIN direction.

Through the above adjustment, the adjustment of the photoelectric switch of the pallet wrapper is over, no matter whether the photoelectric is easy to use or not, there are already results.

Tags: Pallet wrapper

Recent Comments