You may need a column type jib crane

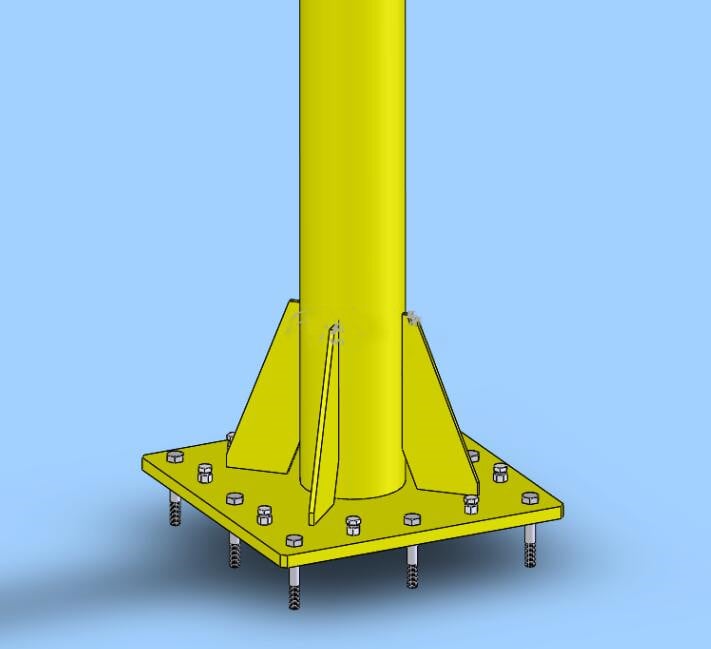

The working strength of the jib crane belongs light model. The crane is composed of a column, a slewing cantilever, a slewing drive device and an electric hoist. The lower end of the column is fixed on the concrete foundation through anchor bolts. Run left and right straight on the cantilever I-beam, and lift heavy objects.

The cantilever of the crane is a hollow steel structure, which has the advantages of light weight, large span, large lifting capacity, economy and durability. The built-in traveling mechanism adopts special engineering plastic traveling wheels with rolling bearings, which has small friction and brisk walking; the small structure size is especially conducive to improving the hook stroke.

Column type jib crane is also called fixed column or column mounted cantilever crane. It’s a freestanding jib crane and the lifting capacity is 125Kg-5000Kg, various track types and spans, and the prefabricated standard modular design makes it easier to expand and move. It can be installed on any ordinary 15 cm thick reinforced concrete ground, and can be customized according to customer needs as a flexible lifting equipment. Similar model also has the wall mounted jib crane, which the difference is fixing on walls.

The column type jib crane has the advantages of novel structure, reasonableness, simplicity, convenient operation, flexible rotation, and large working space. Lifting and transporting heavy objects in work, warehouses, docks and other occasions.

At the same time, for the operation of small workpieces, the column type jib crane is also the best solution to be used in conjunction with other equipment. This includes install the column-type jib crane next to the coil wrapping machine, it is very convenient to feed the heavy steel coils to the wrapping station of the steel coil wrapper. For small injection molds and stamping molds, the column-type jib crane can easily and conveniently lift the mold and place it on the turning table of the mold tipper machine. Quickly flip the molds, which greatly saves operating time and improves work efficiency.

Tags: mold flipper, Upender and tilter

Recent Comments