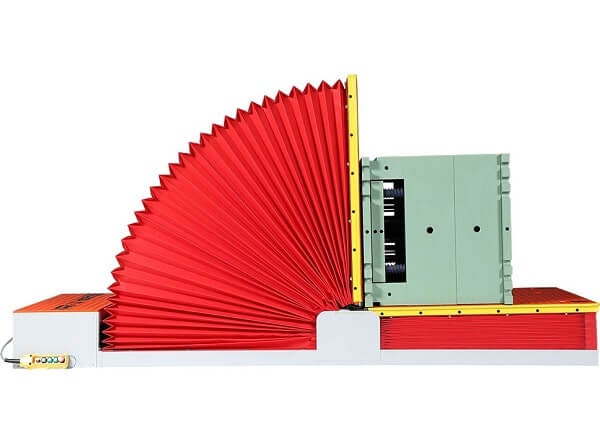

Mold flipper is the machine designed and made for turning injection molds and casting die. The machine is used when repairing the moulds, it’s more convenient and safer to turn over the mold and die body to a new sides compare to flip by using hoist, chain and flipping rack. The machine is also have full electrical and hydraulic powered models, which you can choose the most suitable model that fits to your working environment and requirement.

- 90 degree turn over to change the injection molds and casting die to ideal direction;

- Electrical model with chain and gear sprocket mechanism to power the machine;

- Separated control cabinet away from the turn over machine, keep the safety of personnels;

- Four steel made wheels to support the heavy loads.

| Turn over degree | 90° |

| Max load | 5/10/15/20 tons |

| Platform size | Customized |

| Turn over speed | 30-90 sec/90° |

| Power supply | 380V/50Hz/3Ph |

| Output | 3Kw…. |

- 90 degree turn over to change the injection molds and casting die to ideal direction;

- Hydraulic power system and mechanism to drive the machine;

- Available to realize 180 degree rotation by flipping the molds twice;

- Separated control cabinet away from the turn over machine, keep the safety of personnels;

- Dual platforms are available to flip, suitable for loading the heavy molds by hoist/crane.

| Turn over degree | 90°/180° |

| Max load | 5/10/15/20 tons |

| Platform size | Customized |

| Turn over speed | 30-90 sec/90° |

| Power supply | 380V/50Hz/3Ph |

| Output | 5.5Kw…. |

More accessories and special design or customization are acceptable, welcome to contact our team with your specific requirement and data information.