What is a Freezer Spacer Removal Machine?

Freezer spacer removal machines are specifically designed to meet the increasing demands and heavy workloads of meat processing plants and cold chain facilities. Remove freezer spacers, combine loads and change pallets in seconds. The machine control system is simple with very limited buttons, the components are reliable, and the operation is convenient. Available in a variety of options and stock sizes.

Application of Freezer Spacer Removal Machine:

Our freezer spacer removal machine can serve any industry that uses freezer dividers/freezer spacers, which used for allowing cool air to flow between containers and promoting faster, more efficient freezing. Industries that use them extensively include frozen food and refrigeration, warehousing and distribution, wholesale grocery, and meat and poultry processing. It can also do “double duty” by acting as a pallet changer – you can use them to change shipping pallets for system pallets.

Faster, Safer Processing

Using a freezer spacer removal machine is faster and safer than manually repacking trays after the freezing process, our freezer spacer removal machine offers many valuable advantages:

- No manual lifting required.

- The risk of the product being dropped or damaged is very low.

- Much faster than manual unstacking.

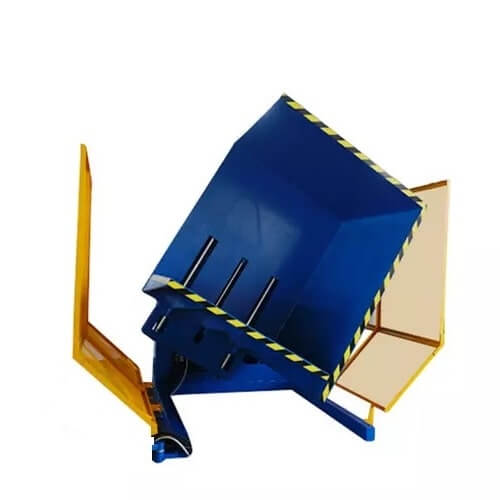

FZ-PE consists of pallet reclaimers and freezer shelf removers to handle the heavy-duty challenges posed by cold chain facilities and meat processing workshops. Use them to rotate the palletized loads at a 110 degree angle for quick removal of the freezer dividers. You can also find online systems designed for automating the entire freezer divider removal process, making them ideal for high throughput material handling operations.

FZ-PT is a reliable system for inserting and removing freezer spacers at an impressive rate of 25-30 loads per hour. It includes an inward-tipping basket for easy removal of trays and freezer spacers. It offers significant labor savings: it can eliminate up to 95% of the manpower required to manually insert or remove the dividers. It’s versatile which can accommodate single or double loads and can also replace damaged pallets. Great capacity available to work with boxes/containers stacked on pallets that are 79″ tall or even higher.

Recent Comments