How to Make 6 Sides Wrapped Package by Pallet Stretch Hooder and Pallet Inverter?

The pallet stretch hood machine ensures the safety of goods by increasing the clamping force of the film and prevents goods from overturning during transportation or storage. Provide users with reliable, durable and high-performance terminal packaging solutions. The stretch hood film requires at least 1.6 tons of pulling force to be pulled apart and covered on the goods. If it is maliciously violated, it cannot be restored manually. Stretch hood film also has high puncture resistance, providing full-pallet protection for goods. Cold stretch hood technology is ideal for pallet transfer. In fact, a high level of stability can be achieved with just one layer of film, even for the most irregular pallet sizes. The clamping force of the film will secure the goods to the pallet so they can be safely handled and transported.

Compared with stretch film wrapping machine:

- The stretch hooder uses tubular film to wrap the pallet. The film will automatically adapt to the goods and protect the 5 sides of the goods, greatly saving the consumption of film. The stretch film packaging equipment needs to be repeatedly wrapped multiple times around the periphery of the goods.

- Stretch hood packaging is a complete five-sided packaging that provides waterproofing and protects goods from external factors such as wind, dust, UV rays, and even moisture, rain and snow. The top of the goods packaged in stretch film lacks protection and cannot resist rain erosion.

- Because there is only one layer of the stretch hood packaging, it is completely transparent and can clearly identify the brand of the goods and the content of the label. The transparency of stretch film packaging is low, and the readability of barcodes is not strong.

- Stretch hood packaging requires a force greater than 1000kgf to pull the film apart and set it on the surface of the goods, which is irreparable. Any infringement of the cargo is easily detected as there is only one layer of film and there are no wrinkles or film build-up. Reduce product losses due to theft.

- In addition to the high transparency of the film, the film bag wrapped on the goods is tight and neat. The company logo can also be printed on the surface of the film in advance to enhance the brand recognition of the product at the point of sale or during transportation. Neat and professional packaging will also positively affect buyers’ attitudes and promote consumer purchasing behavior.

- Stretch hood packaging is very fast, the maximum packaging capacity can reach 200 pallets per hour.

- There is still good clamping force and stability from -20C to 0C, and the clamping force perpendicular to the film direction is significantly improved, so the palletizing stability is good. Even if the pallet is tilted up to 30 degrees, the palletized goods will not overturn.

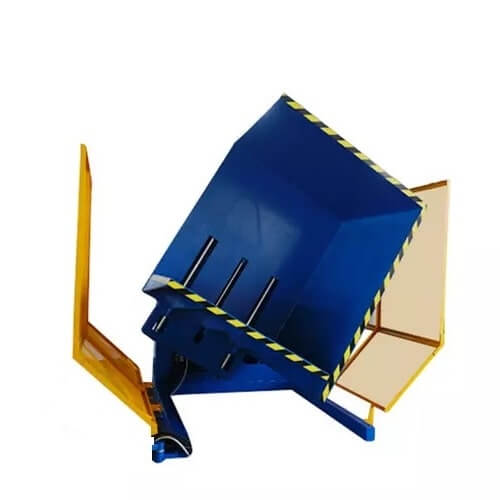

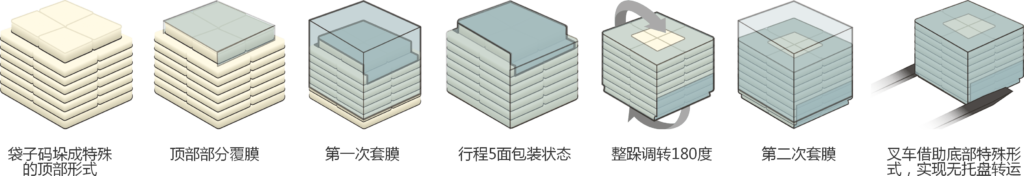

Stretch hood film not only adds stability to the pallet, but also can provide 6-sided reliable dust-proof and waterproof protection for the goods, protecting the packaged goods from the weather. Even if the goods are placed outside, there is no need to worry about getting soaked by rain or snow. In order to further improve the stability of the goods, we can use a pallet inverter to reinforce the packaging of the goods, that is, wrap and turn the goods repeatedly to achieve multi-layer wrapping.

This technology requires the goods to be packaged twice. The second time the goods must be turned upside down 180°, and finally a 100% waterproof self-standing package is obtained. This method of operation also enables pallet-free packaging. Palletless packaging technology is specially designed for bagged products. It can produce stable, safe, compact and self-supporting storage and transportation status without the use of wooden pallets. This state is very suitable for forklift transportation, and the final packaging state of the goods forms a space for forklift lifting.

Stretch hood technology is a stable, waterproof, compact load solution, ideal for packaging of all goods, including heat-sensitive materials. The packed pallets can be stored in the open air and UV protection can be added.

Tags: 180 degree pallet turning machine, Pallet wrapper

Recent Comments