Low cost manual mold flipping tool

In the workshops of plastic injection and metal casting industries, it is often to see the work of turning over the plastic injection moulds and casting dies when there is repairment needed. Workers need to tilt the molds and dies 90 degree to make it easy for repairment. This operation could be very easy when the molds and dies are small and light. But it could be difficult and dangerous when the molds and dies are very heavy and big.

Most of the times, injection moulds and casting dies are often weight about 5-10 tons or even heavier. So it’s not convenient to make the flipping but manual work, and mold flipper is a perfect machine to make the turn over process continued smoothly and reliably. This mold flipping machine has round turn over body with two flat platforms against each other vertically. We can place the moulds and dies onto the platform and press the start button, the mold flipping machine will smoothly rotate and turn over 90 degree to make the mold tilt to a new position which is good for repairment.

There is no doubt to say this mold flipper is a perfect machine for turning the injection molds and casting dies. But this mold flipping machine could be a high investment for some of the small business owners. And what if I only need to flip the molds few times a week? It seems not that reasonable to invest such a big machine for just a very small throughput. But how can we manage to turn over the heavy molds safely?

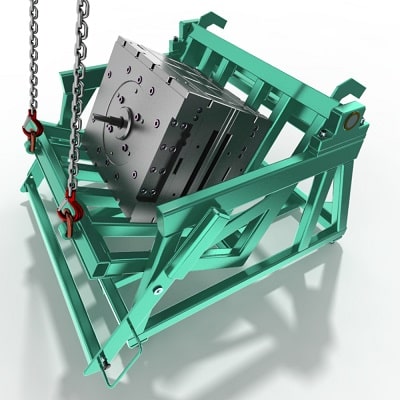

This manual mold flipping tool could be a suitable equipment to solve your problem. It’s a mechanical turning device with no electrical motor, relies on the lifting equipment such as hoist to finish the turn over procedure. This manual mold flipping tool has a basket to handle molds and dies within 5 tons and length, width, height less than 1 meter. It’s fast to flip molds by this mold flipping tool, only about 2 minutes we can finish the turning process of 1 molds. Most importantly, this is a very economical solution compare to the electrical model. The low cost and cheap price make it easy to affordable to everyone. Investors could even buy few sets together to used in different line and workshops, improve their work efficiency.

Tags: mold flipper, Upender and tilter

Recent Comments