Upender Machine Made by Emanpack to Help Your Loading Process

Emanpack is a professional upender machine provider based in China, including pallet tipper machines, mold tipper machines, and steel coil upender machines. Widely used in the replacement of warehouse cargo pallets and the turning needs in mold maintenance work. Steel coil upender machines provide an efficient and safe way to turn and load steel coils, aluminum coils, and wire coils of various diameters onto the uncoiler.

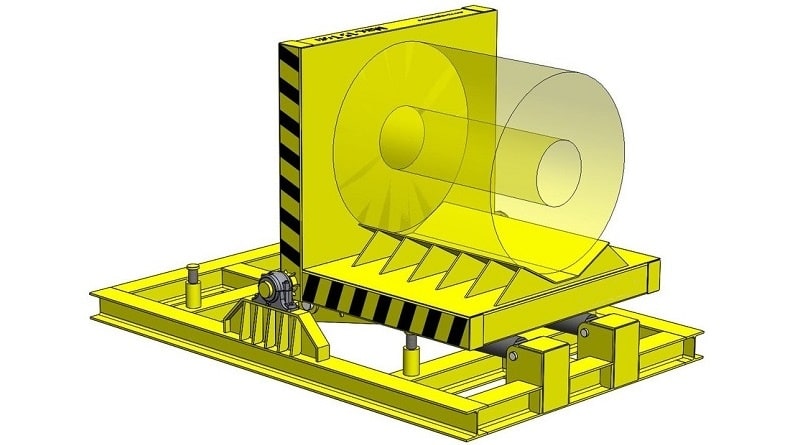

Wire Coil Upender Machines

Emanpack’s wire coil upender machines are efficient and user-friendly additions to any coil production line. This upender machine allows the operator to load the wire coils from the pallet onto the loading table and then rotate the wire coils upright. The use of the upender machine enables the operator to pre-prepare the wire coils while the uncoiler is still running on the production line, thereby improving the efficiency of the production line. In addition, the use of the wire coil upender machine also greatly reduces the possibility of damaging the uncoiler due to direct loading of coils using other methods.

Standard Features of Upender Machine

- Heavy-duty structural design with high load capacity and greater adaptability;

- V saddle is used to reduce damage to the outer diameter of the coils during the turning process;

- Adjustable fixed arms for manual turning;

- Hydraulic motors, 4-wheel drive traverse, strong power;

- Hydraulic cylinders drive lifting and turning, simple structure and simple daily maintenance;

- Hydraulic circuit flow control, cross port check and blocking center solenoid valves, powerful functions and precise control;

- Customizable designs can meet customers’ specific needs;

- Optional barrier protection around the equipment to prevent unauthorized intrusion by strangers.

These upender machines have a large vertical travel range and can accommodate coils of various outer diameters. Hydraulic cylinders are used to drive and lift the coils for the turning table. Flow control, cross port check valves and blocking center solenoid valves are directly incorporated into the hydraulic circuit to control speed and prevent unnecessary movement when power is off.

Tags: Upender and tilter

Recent Comments