Precautions for the use of pallet stretch wrap film packaging machine

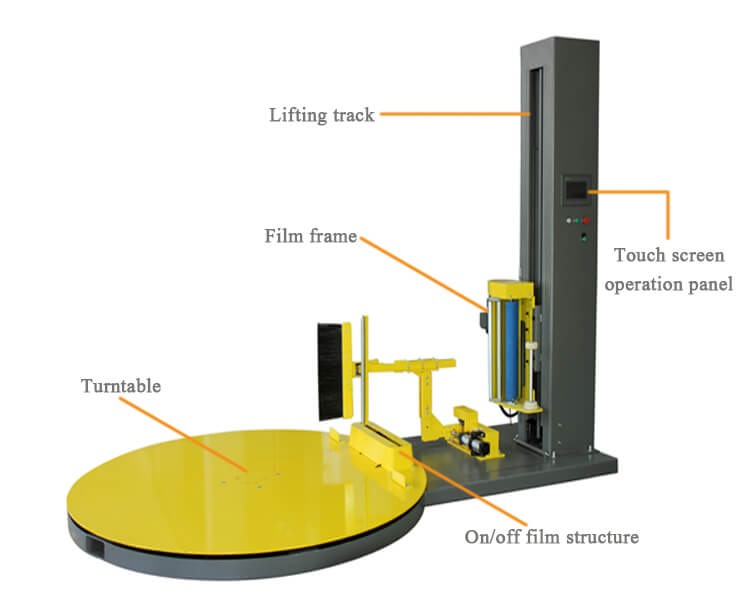

After purchasing the pallet stretch wrapping machine, users are generally concerned about how to use it.

The latest developments of the company Regarding the use of stretch wrap film pallet packaging machine matters needing attention. What are the operating specifications for operating the stretch wrapping machine? Here are some options for you to choose from:

1. Install the device according to the steps in the instruction manual.

2. Turn on the supporting power supply and set the machine parameters correctly.

3. When replacing the film roll, press the emergency stop switch to ensure that the parts of the whole machine are stationary.

4. Understand the safe operating range of the pallet stretch wrap film machine. In actual operation, there are often goods that exceed the pallet range. Sometimes, in order to save costs, users will also use equipment to pack items that exceed the size of the pallet. Before the machine runs, if the operator does not notice this, it is easy to cause scratches, collisions, scratches or losses between the goods and the equipment.

5. When the pallet stretch wrap machine is running, the operator should keep a certain safe distance from the machine’s emergency stop device, so that the machine can be stopped quickly when the machine is under special circumstances.

6. Ensure that the goods are lightly loaded and unloaded, to avoid deformation and damage to the chassis, and to ensure that the height of the goods is within the packaging range to achieve a good packaging effect.

One Reply to “Precautions for the use of pallet stretch wrap film packaging machine”

Comments are closed.