Corrugated pipe PE/PVC hose coil stretch wrapper packing machine from Eman team

There are many ways to connect HDPE pipe, such as butt welding, electric fusion welding, socket welding, extrusion welding and so on.These joints are heated to form a completely uniform and clean joint, making the weld as strong as the pipe itself, and possibly stronger than the previous weld on either side of the pipe.The welding process does not require rubber seals or other pipes such as PVC pipes, which can cause environmental pollution and health hazards and increase the likelihood of failure over time.HDPE/PE pipe PVC hose coil packing machine stretch wrapper machine from Eman team. The PE pipe itself is not prone to root invasion, and even when installed in soft soil, it ensures the integrity and corrosion resistance of the pipe.

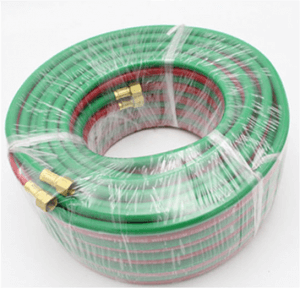

hose coil wrapping machine

The HDPE communication conduit uses a fusion welding system that eliminates the need for anchors or thrust blocks to help hold the conduit in place. The weld is sufficient to resist the weight load on both ends, thus reducing material costs and saving installation time.In the future, there will be no potential safety hazard when the soil is excavated close to the pipeline, which is particularly critical and important for the high-pressure natural gas pipeline.

corrugated pipe hose coil stretch wrapping machine

Polyethylene pipes packaging machine in vertical machine. can be installed without trenches, which is safer and more convenient, with less interference and damage to the surrounding environment.

Tags: Hose coil wrapping machine

One Reply to “Corrugated pipe PE/PVC hose coil stretch wrapper packing machine from Eman team”

Comments are closed.